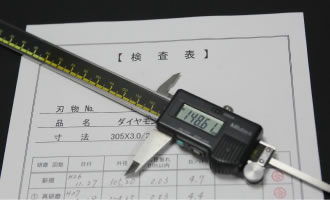

Original tool control system integrated with latest technology

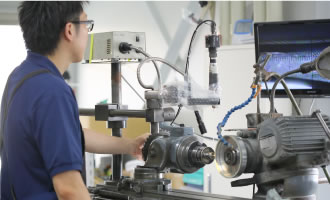

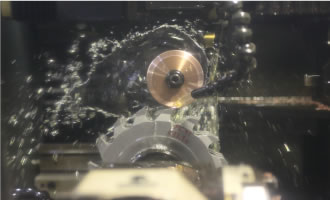

After receiving your tool for re-grinding, we carefully examine its state and check for wear, chip and other damages so that we can propose an optimal repair with reasonable cost. We re-grind tools one by one and bring them back to life and make them as good as new.

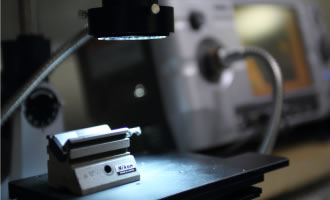

With strong sense of responsibility, we are determined to offer you the highest quality and accuracy, making the best possible use of our original tool control system as well as exactly the same re-grinding equipment and test devices which are also used for new tools.