KobaCut is the Flagship model with all our might.

This is where you find all our accumulated expertise and techniques combined with the latest technology.

KobaCut is the trademark registered for patent. This term is exclusively given to our true masterpieces.

Followed by KobaCut V described below, many new models are going to be launched one after another.

KobaCut V is a diamond V cutter which gives an amazing impact on V grooves of aluminium and copper boards.

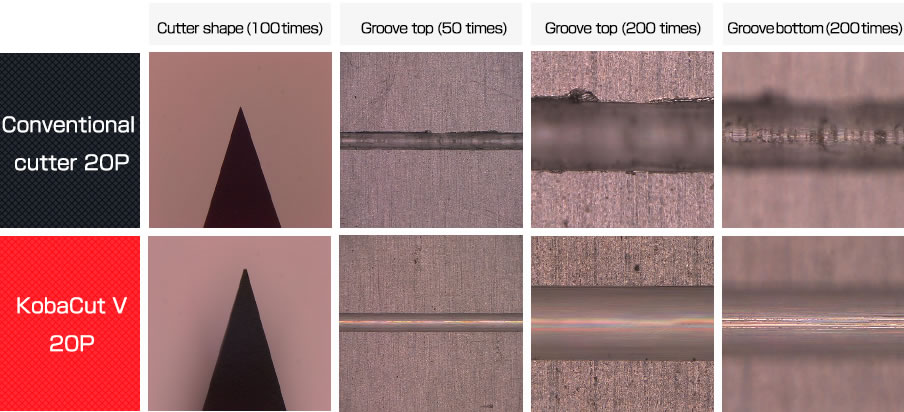

It realises superior quality for the finish of the cut section, which is unthinkable with conventional cutters.

With lower resistance, it has become possible to precisely process a V groove on a LED aluminium plate which is hard to be processed with accuracy. At one major manufacturer of circuit boards in Japan, KobaCut is utilised together with V cutting machines instead of press punching molds as a division processing method of LED aluminium plates for LCD TVs. Division process with a punching mold produces quite a volume of waste, whilst waste can be minimised if a V groove is cut vertically and laterally. We recommend a V cutting machine manufactured by SOFMIX who is our partner.

KobaCut V is capable of cutting an aluminium or copper boards of 1 mm thickness at the speed of 10 to 15 m RPM. Not to mention it also realises superb precision and smoothness on the cut surface. KobaCut is at the height of its cutting speed. Still maintaining precision, it can run at double the speed of that of a conventional V cutter which can do so only at within 4-6 RPM.

In comparison with conventional cutters, highly advanced precision of groove processing precision Difference in residual thickness is highly improved. Please refer to technical references below for details.

KobaCut is the Flagship model with all our might.

KobaCut is the Flagship model with all our might.