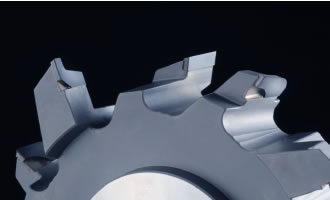

Our technology is built upon fusion of craftsmanship with experiences of hand processing and substantial modern facilities.

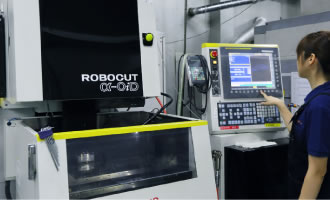

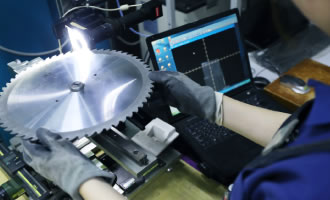

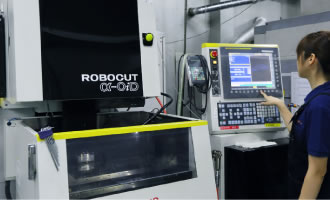

To support any complicated custom-made cutting tool, we own and utilise over 30 NC processing machines equipped with the latest technology, such as electric discharge machines, wire processing machines, NC grinders of VOLLMER and WALTER from Germany, ANCA from Australia and so on.

CNC electric discharge machine of VOLLMER

Electric discharge polishing with the CNC processing machine of WALTER

Wire electric discharge machine of FANUC