Kobayashi DIA offers you fully customised designing and manufacturing of cutting tools suitable for your needs. We propose a highly cost-effective tool originally made for you, targeting cost reduction by means of tool life improvement with cut material characteristics, not to mention environmental factors such as machines and manufacturing lines, taken into account. Equipped with latest technology, our skilled engineers team up and and realise your ideal.

We take qualities of cut material, manufacturing environment and other details into account. Zero-based design therefore enables to offer you cutting tools ideal for you. Kobayashi DIA's cutting tool can let you expect improvement of cutting capacity.

It will make your production efficiency greatly higher and operation environment more improved.

Together with customers, Kobayashi DIA challenges ourselves to make tool life longer. Longer tool life provides reduction in running cost and productivity improvement with a great impact, which will give high cost-effectiveness.

Data of design, manufacturing and inspection values are thoroughly controlled in the original system for cutting tool control.

Fast and assured service is therefore available. Thorough support until re-grinding is available. Please feel assured and leave it to us.

Our technology is built upon fusion of

craftsmanship with experiences of hand processing

and substantial modern facilities.

To support any complicated custom-made cutting tool,

we own and utilise over 30 NC processing machines equipped

with the latest technology, such as electric discharge machines,

wire processing machines, NC grinders of VOLLMER

and WALTER from Germany,

ANCA from Australia and so on.

Our engineers from different areas of expertise team up and hear your concerns. We propose a fully customised tool ideal for your needs.

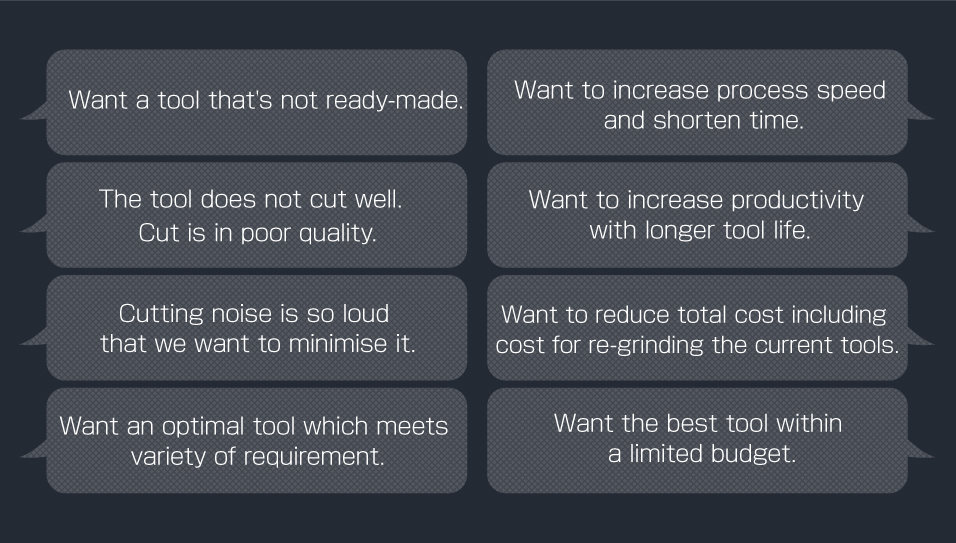

Please contact us if you have such demands and concerns as below.

We believe we make perfect tools together with customers.

We are able to design a tool to meet your demands based on provided information of machines, process requirement and usage.

Please give us as much information as possible.

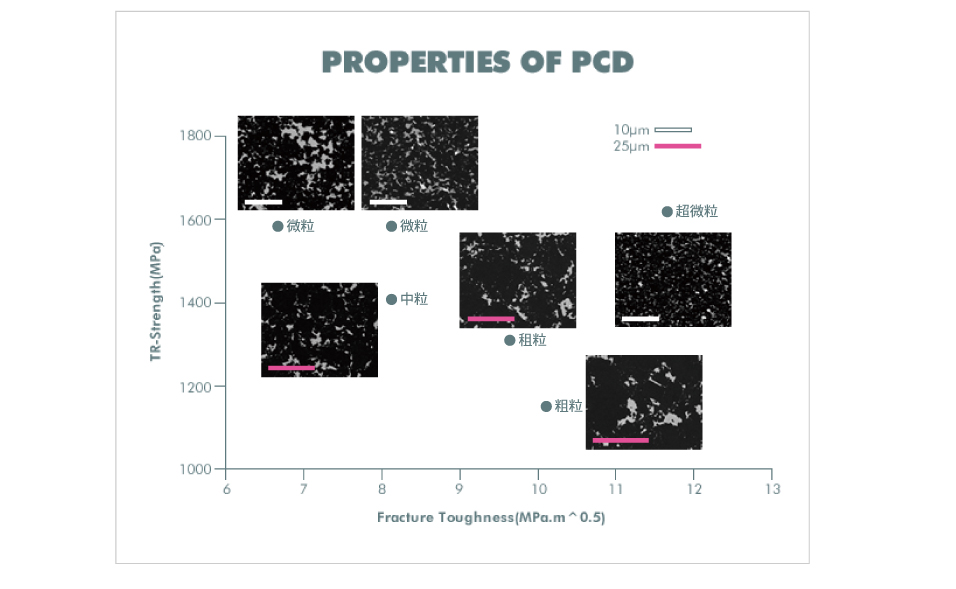

Poly Crystalline Diamond is called PCD for short.

It is made from diamond powders which are heat-treated at high temperature and pressure.

Vicker's hardness of PCD is HV600-HV8000.

For its superior wear resistance, it is suitable for cutting tools and wear-resistant tools.

PCDs used in our diamond tools are carefully selected from inside and outside Japan.

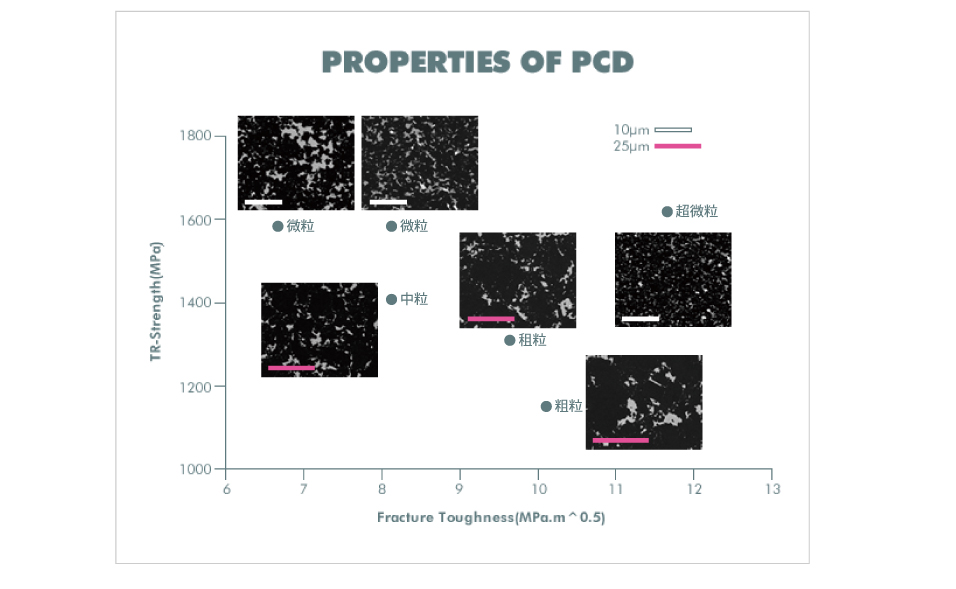

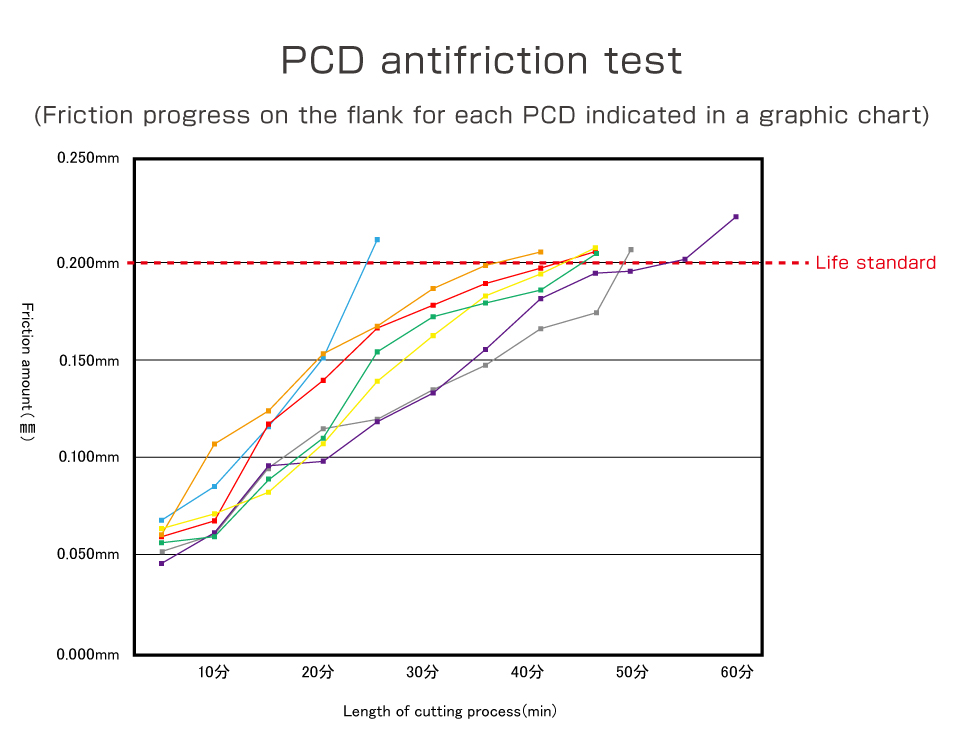

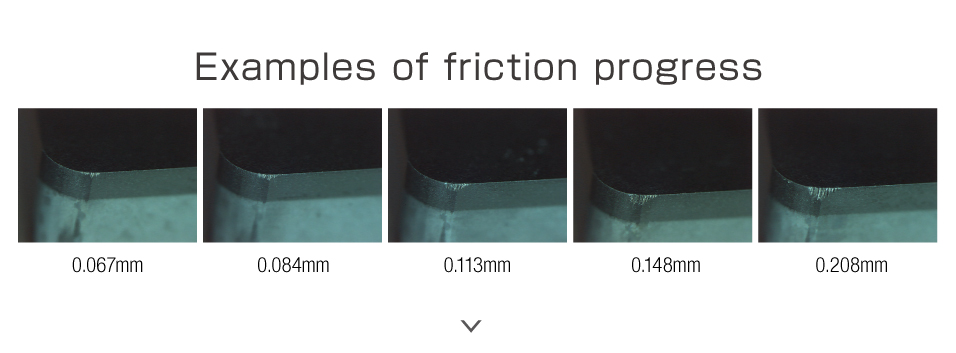

PCDs have many quality grades depending on diamond content and particle sizes.

It is important to select the one ideal for your cut material and cutting requirement.

This is where all expertise we acquired over the years are complied.

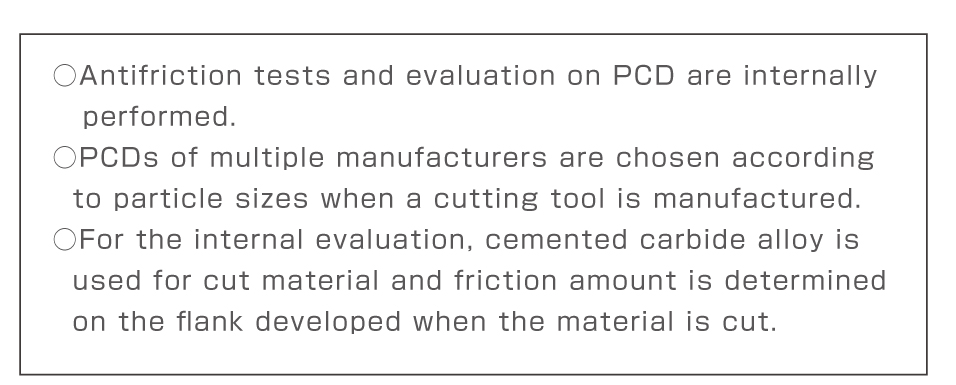

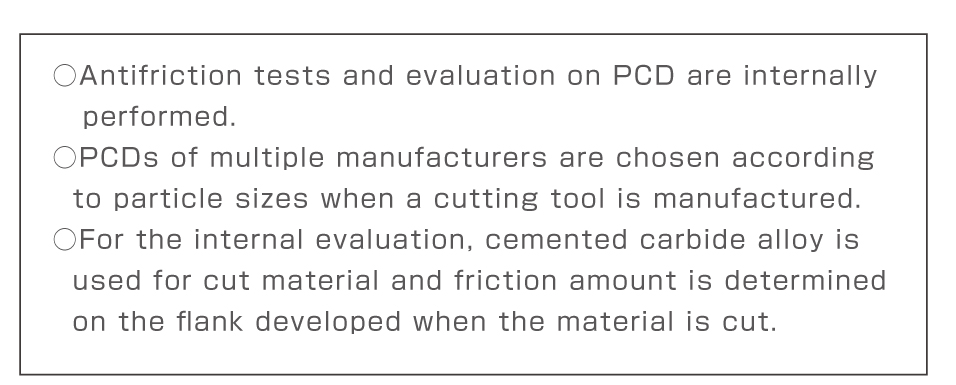

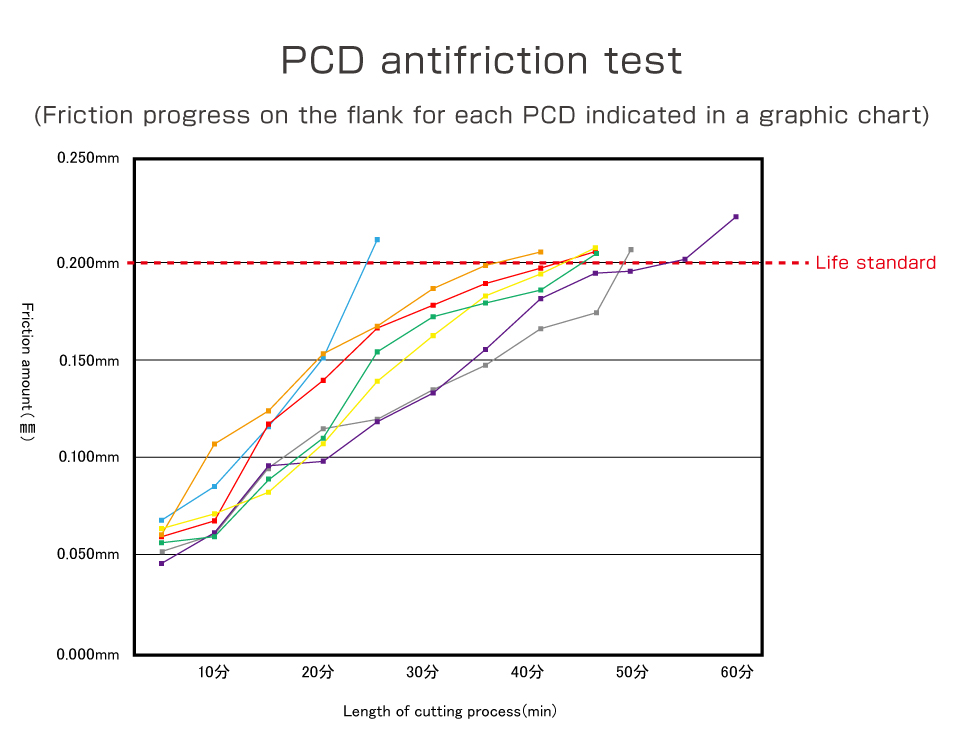

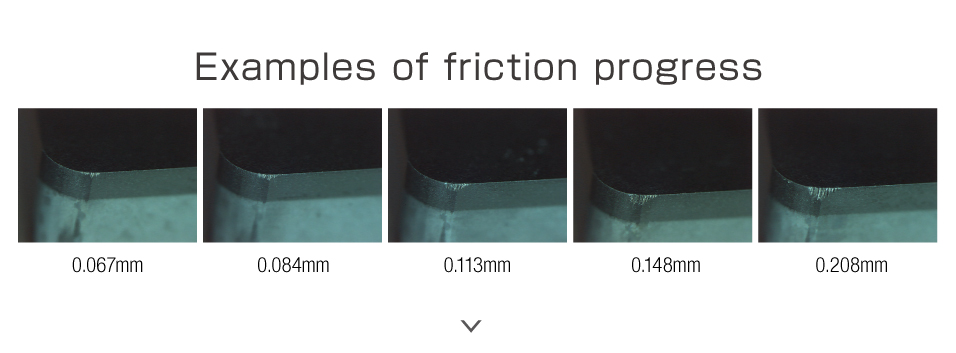

Variety of PCD in different grades is available for selection supported by a number of PCD manufacturers

we deal with. However, only the ones which passed our internal analysis

and antifriction tests are eligible for selection.

We recommend our diamond cutting tools simply

because we perform such tests.

Copyright ©2015 Industrial Diamnd Tools Kobayashi DIA, Ltd All rights reserved.