Processing equipment

Processing equipment

Ultimate PB processing equipment that Kobayashi DIA recommends

Standard cutters installed in SOFMIX processing machines are designed and manufactured by Kobayashi DIA.

V-scoring machine VMS-500

Productive and compact precision V-scoring machine

V-scoring machine VVMS-700CA

V-scoring machine with high quality camera aligning system, capable of max 710 mm processing length

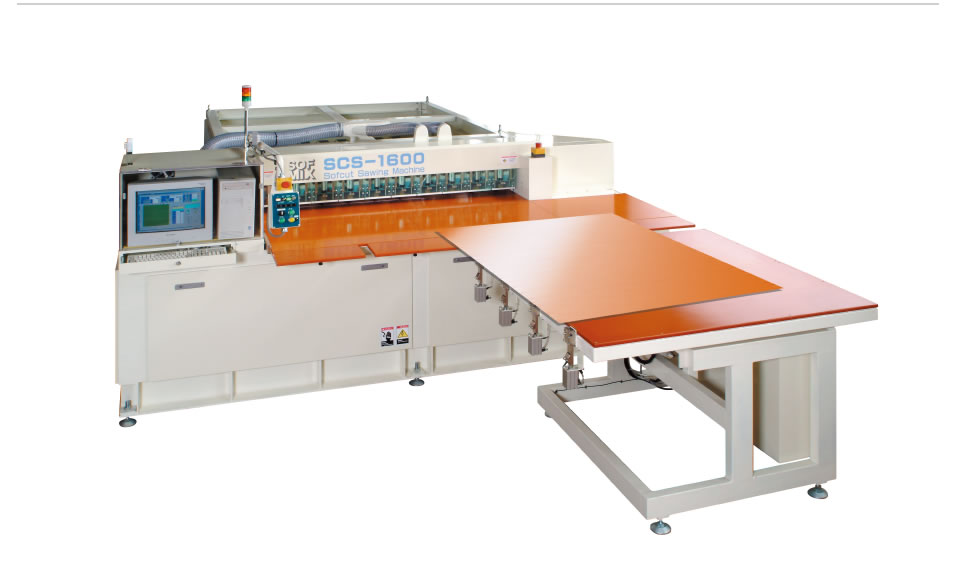

High precision sawing machine SCS-1600

All sawing technology is compiled into this long-awaited masterpiece with anti-burring ability(dual cut).

Trimming and bevelling machine for multilayer PWB HME-650W/WF

Innovation for the trimming process of multilayer PWB. Outer-shape trimming system for the Multilayer PWB is changed.

4-side thin panel bevelling machine MMD-650

Automatically process 0.06 to 1.6mm plated PC boards and removes burrs form them.

Auto-bevelling machine for gold plating contact & module board

Easy and high-precision Bevelling system for contacts.Make an inquiry here

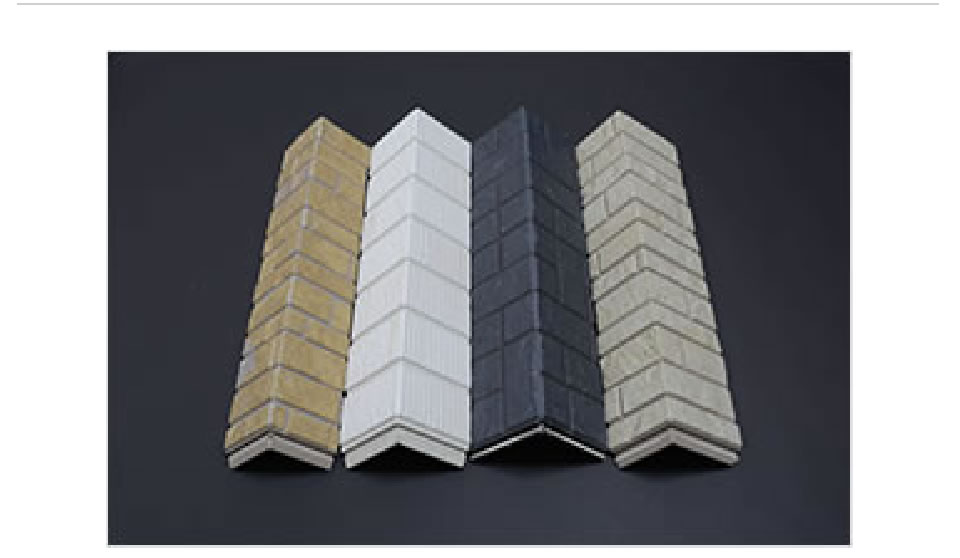

Highly energy-saving gluing system for siding external angle !

The gluing system of Green Wall utilises the combination of an auto glue application device "Unikko" and a large-sized gluing device "Uni oh", enabling the best adhesion performance of PUR hot melt.

Auto glue application device "Unikko"

Application device specially made for PUR hot melt. It can apply melt evenly. Pre-heater is installed within Yunikko to heat siding boards up to the optimal temperature for PUR hot melt application. Approx. 4 kw of energy is consumed. (Pre-heater, pre-heater for glue, motor etc.) PUR hot melt is optimal for application of homogeneous siding material external angles, which is developed by Kobayashi DIA and Ohshika Co., Ltd.

Large-sized application device "Yuni-oh"

No energy is consumed because of full manual operation. 6 short pieces or 1 long piece of material can be installed per row in 8 rows aligned around the drum-shape body.

Make an inquiry here